Discovery of LemonZest

LemonZest Information

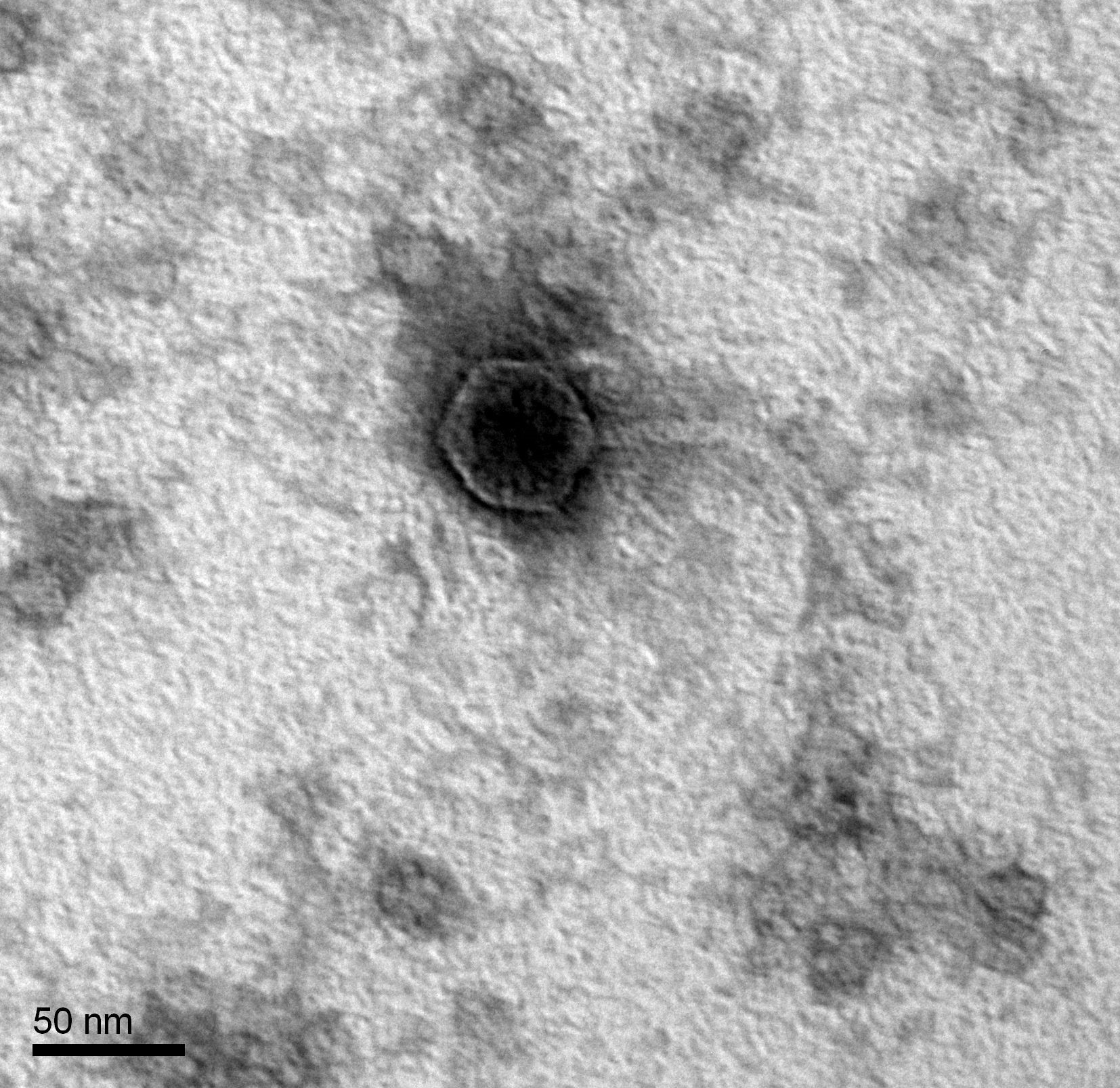

Morphology: Siphoviridae

Sample Collection

| Collector Name |

Dasire Brawley | Ivy Adame | Ivy Adame | Dasire Brawley | |

| Sample No. | 1 | 2 | 3 | 4 | |

| Date of Collection | 8/30/2021 | 8/29/2021 | 9/02/2021 | 9/08/2021 | |

| Sample Type | Soil | Soil | Soil | Soil | |

| General Location | Comanche, TX | Granbury, TX | Garland, TX | Dublin, TX | |

| Location Description | The front yard of a residence within city limits | Ant pile between a parking lot and bike trail | The backyard of a residence within city limits | The top layer of soil that is at an incline leading to the underside of a tree | |

| GPS Coordinates | 31.90340, -98.60686 | 32.4457626, -97.7867877 | 32.8599227, -96.5786044 | 32.0492406, -98.3859251 | |

| Sample Depth | 6 inches | 0-1 inches | 0-1 inches | 0-1 inches | |

| Ambient Temperature | 22°C | 29°C | 28°C | 22°C |

Isolation/Purification

Title: Direct Isolation

Date: August 30, 2021 Redo: No Sample: #1

Purpose: This procedure is to find bacteriophages within our collected soil sample through Direct Isolation.

Notes:

- The following materials were collected: environmental sample, liquid PYCa media, host bacteria (250μl), sterile 3ml or 5ml syringe, 0.22 μm syringe filter, 5ml serological pipette, microcentrifuge tubes, 15ml conical tube, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The original 15ml soil sample #1 was halved into another 15ml tube.

- The original soil sample #1 (now halved) was stored in the fridge.

- The microcentrifuge tube to be used for isolation was labeled “Direct Isolation” with the initials of the group members and the date of 8/30/2021.

- PYCa media was added to the 7.5ml (half of the original 15ml) soil sample via serological pipette until submerged and with about 2ml of media above the sample.

- The working soil sample was inverted a few times to get saturated with the media.

- The soil sample was added to a shaking incubator for 1-2 hours at 250rpm.

- The soil sample was moved to the fridge for a few hours.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- The sample was placed in the centrifuge for 10 minutes at 4℃ to further separate the soil sample and liquid media containing bacteriophages before filtration.

- A 5ml syringe was attached to a 0.22μm filter.

- Approximately 3ml of the top of the flooded soil sample was removed from the tube via a serological pipette.

- Approximately 0.75ml of the flooded sample was filtered into a microcentrifuge tube with a 0.22μm filter.

- The microcentrifuge tube was immediately capped.

- 500μl of the filtrate was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and filtrate was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into the tube of m. foliorum and filtrate.

- Immediately after releasing the top agar into the tube, the top agar and bacterial host/filtrate were aspirated and placed in a petri dish.

- The petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once the mixture solidified, the petri dish was flipped over and placed in the incubator for approximately 2 days.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of the plate, Sample #1 was trashed in the autoclave.

Results:

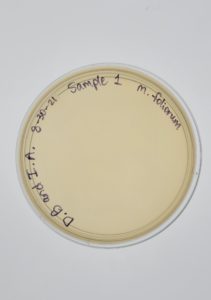

Direct Isolation completed on Sample #1 wielded unsatisfactory results with no plaques formed.

Conclusions and Next Steps:

A Serial Dilution 1:1000 will be performed to confirm or deny the presence of bacteriophages in the sample.

Title: Serial Dilution 1:1000

Date: September 1, 2021 Redo: Yes Sample: #1

Purpose: This procedure is to find bacteriophages within our collected soil sample through Serial Dilution 1:1000

Notes:

- The following materials were collected: phage samples for isolation, purification, or titering; host bacteria (250μl), agar plates, phage buffer, molten top agar (between 55 – 60 ˚C), microcentrifuge tubes, 5ml serological pipettes, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- Three microcentrifuge tubes were each filled with 90μl of phage buffer via micropipette.

- The microcentrifuge tubes were labeled 1:10, 1:100, and 1:1000 respectively.10μl

- 10μl of the sample filtrate was pipetted via micropipette into the 1:10 labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of the sample filtrate/phage buffer was pipetted via micropipette from the 1:10 labeled microcentrifuge and placed in the 1:100 labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the sample filtrate/phage buffer was pipetted via micropipette from the 1:100 labeled microcentrifuge and placed in the 1:1000 labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the 1:1000 dilution was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and filtrate were gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into the tube of m. foliorum and filtrate.

- Immediately after releasing the top agar into the tube, the top agar and bacterial host/filtrate were aspirated and placed in a petri dish.

- The petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once the mixture solidified, the petri dish was flipped over and placed in the incubator for approximately 6 hours.

- The workbench was cleaned and disinfected as described in Steps #2-4.

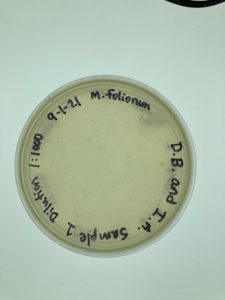

- 6 hours after placing the petri dish into the incubator, Sample #1 through Serial Dilution was discovered to be contaminated.

- After a photo and observations of the plate, Sample #1 was trashed in the autoclave.

Results:

The Serial Dilution 1:1000 yielded contaminated results. The group members are currently unsure of what could have caused the contamination and will seek clarification from the TA.

Conclusions and Next Steps:

Group members will collect a new sample and start the Direct Isolation phase. Group members will be more cautious with the next sample, carefully completing each step close to a burner flame to ensure contaminants are also not an issue.

Title: Direct Isolation

Date: August 30, 2021 Redo: No Sample: #2

Purpose: This procedure is to find bacteriophages within our collected soil sample through Direct Isolation.

Notes:

- The following materials were collected: environmental sample, liquid PYCa media, host bacteria (250μl), sterile 3ml or 5ml syringe, 0.22 μm syringe filter, 5ml serological pipette, microcentrifuge tubes, 15ml conical tube, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The original 15ml soil sample #2 was halved into another 15ml tube.

- The original soil sample #2 (now halved) was stored in the fridge.

- The microcentrifuge tube to be used for isolation was labeled “Direct Isolation” with the initials of the group members and the date of 8/30/2021.

- PYCa media was added to the 7.5ml (half of the original 15ml) soil sample via serological pipette until submerged and with about 2ml of media above the sample.

- The working soil sample was inverted a few times to get saturated with the media.

- The soil sample was added to a shaking incubator for 1-2 hours at 250rpm.

- The soil sample was moved to the fridge for a few hours.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- The sample was placed in the centrifuge for 10 minutes at 4℃ to further separate the soil sample and liquid media containing bacteriophages before filtration.

- A 5ml syringe was attached to a 0.22μm filter.

- Approximately 3ml of the top of the flooded soil sample was removed from the tube via a serological pipette.

- Approximately 0.75ml of the flooded sample was filtered into a microcentrifuge tube with a 0.22μm filter.

- The microcentrifuge tube was immediately capped.

- 500μl of the filtrate was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and filtrate was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into the tube of m. foliorum and filtrate.

- Immediately after releasing the top agar into the tube, the top agar and bacterial host/filtrate were aspirated and placed in a petri dish.

- The petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once the mixture solidified, the petri dish was flipped over and placed in the incubator for approximately 2 days.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of the plate, Sample #2 was trashed in the autoclave.

Results:

Photo (soon to be added): Sample #2 After Direct Isolation Completed; No Plaques Formed.

Conclusions and Next Steps:

Direct Isolation completed on Sample #2 wielded unsatisfactory results with no plaques formed. The addition of molten agar too quickly resulted in the mixed agar and Sample #2 being unable to settle or solidify for approximately 45 minutes. Will Proceed with more caution with the next sample, carefully completing each step close to a burner flame to ensure contaminants are also not an issue.

The next steps include collecting a new soil sample and completing Direct Isolation and Serial Dilution 1:1000.

Title: Serial Isolation 1:1000

Date: September 1, 2021 Redo: Yes Sample: #2

Purpose: This procedure is to find bacteriophages within our collected soil sample through Serial Dilution 1:1000

Notes:

- The following materials were collected: phage samples for isolation, purification, or titering; host bacteria (250μl), agar plates, phage buffer, molten top agar (between 55 – 60 ˚C), microcentrifuge tubes, 5ml serological pipettes, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- Three microcentrifuge tubes were each filled with 90μl of phage buffer via micropipette.

- The microcentrifuge tubes were labeled 1:10, 1:100, and 1:1000 respectively.10μl

- 10μl of the sample filtrate was pipetted via micropipette into the 1:10 labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of the sample filtrate/phage buffer was pipetted via micropipette from the 1:10 labeled microcentrifuge and placed in the 1:100 labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the sample filtrate/phage buffer was pipetted via micropipette from the 1:100 labeled microcentrifuge and placed in the 1:1000 labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the 1:1000 dilution was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and filtrate were gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into the tube of m. foliorum and filtrate.

- Immediately after releasing the top agar into the tube, the top agar and bacterial host/filtrate were aspirated and placed in a petri dish.

- The petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once the mixture solidified, the petri dish was flipped over and placed in the incubator for 24 hours.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- On September 2, 2021, No Photo was taken of the Serial Isolation 1:1000 Sample #2.

- After observations of the plate, Sample #2 was trashed in the autoclave.

Results:

*no photo available for Sample #2 Serial Isolation. Sample #2 was trashed into the autoclave.*

Conclusions and Next Steps:

Serial Isolation 1:1000 completed on Sample #2 resulted in no plaques formed. The theory of researchers concluded that Sample #2 simply had no phages.

The next steps include collecting new soil samples and attempting Direct Isolation once more.

Title: Direct Isolation

Date: 09/02/2021 Redo: No Sample: #3

Purpose: This procedure is to find bacteriophages within our collected soil sample through Direct Isolation.

Notes:

- The following materials were collected: environmental sample, liquid PYCa media, host bacteria (250μl), sterile 3ml or 5ml syringe, 0.22 μm syringe filter, 5ml serological pipette, microcentrifuge tubes, 15ml conical tube, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The original 15ml soil sample #3 was halved into another 15ml tube.

- The original soil sample #3 (now halved) was stored in the fridge.

- The microcentrifuge tube to be used for isolation was labeled “Direct Isolation” with the initials of the group members and the date of 9/02/2021.

- PYCa media was added to the 7.5ml (half of the original 15ml) soil sample via serological pipette until submerged and with about 2ml of media above the sample.

- The working soil sample was inverted a few times to get saturated with the media.

- The soil sample was added to a shaking incubator for 1-2 hours at 250rpm.

- The soil sample was moved to the fridge for a few hours.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- The sample was placed in the centrifuge for 10 minutes at 4℃ to further separate the soil sample and liquid media containing bacteriophages before filtration.

- A 5ml syringe was attached to a 0.22μm filter.

- Approximately 3ml of the top of the flooded soil sample was removed from the tube via a serological pipette.

- Approximately 0.75ml of the flooded sample was filtered into a microcentrifuge tube with a 0.22μm filter.

- The microcentrifuge tube was immediately capped.

- Sample #3, inside of the microcentrifuge tubes were then immediately placed into the fridge until the rest of Direct Isolation is able to be safely completed and surveyed on September 08, 2021.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- September 08, 2021 the other half of the Direct Isolation process began again.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- 500μl of the filtrate was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and filtrate was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into the tube of m. foliorum and filtrate.

- Immediately after releasing the top agar into the tube, the top agar and bacterial host/filtrate were aspirated and placed in a petri dish.

- The petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once the mixture solidified, the petri dish was flipped over and placed in the incubator to be taken out and observed on September 10, 2021.

- The workbench was cleaned and disinfected as described in Steps #2-4.

Results:

Direct Isolation completed on Sample #3 wielded unsatisfactory results with no plaques formed.

Conclusions and Next Steps:

Group members will collect a new sample and start the Direct Isolation phase.

Title: Direct Isolation

Date: September 8, 2021 Redo: No Sample: #4

Purpose: This procedure is to find bacteriophages within our collected soil sample through Direct Isolation.

Notes:

- The following materials were collected: environmental sample, liquid PYCa media, host bacteria (250μl), sterile 3ml or 5ml syringe, 0.22 μm syringe filter, 5ml serological pipette, microcentrifuge tubes, 15ml conical tube, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The original 15ml soil sample #4 was halved into another 15ml tube.

- The original soil sample #4 (now halved) was stored in the fridge.

- The microcentrifuge tube to be used for isolation was labeled “Direct Isolation” with the initials of the group members and the date of 9/08/2021.

- PYCa media was added to the 7.5ml (half of the original 15ml) soil sample via serological pipette until submerged and with about 2ml of media above the sample.

- The working soil sample was inverted a few times to get saturated with the media.

- The soil sample was added to a shaking incubator for 1-2 hours at 250rpm.

- The soil sample was moved to the fridge for a few hours.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- The sample was placed in the centrifuge for 10 minutes at 4℃ to further separate the soil sample and liquid media containing bacteriophages before filtration.

- A 5ml syringe was attached to a 0.22μm filter.

- Approximately 3ml of the top of the flooded soil sample was removed from the tube via a serological pipette.

- Approximately 0.75ml of the flooded sample was filtered into a microcentrifuge tube with a 0.22μm filter.

- The microcentrifuge tube was immediately capped.

- 500μl of the filtrate was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and filtrate was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into the tube of m. foliorum and filtrate.

- Immediately after releasing the top agar into the tube, the top agar and bacterial host/filtrate were aspirated and placed in a petri dish.

- The petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once the mixture solidified, the petri dish was flipped over and placed in the incubator for approximately 2 days.

- The workbench was cleaned and disinfected as described in Steps #2-4.

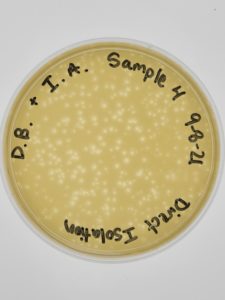

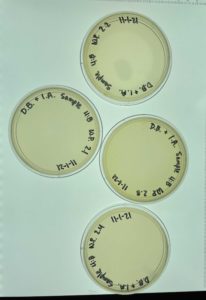

Results:

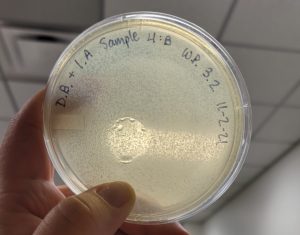

Multiple plaques formed.

Conclusions and Next Steps:

Direct Isolation completed on Sample #4 wielded satisfactory results with multiple plaques formed. Group members will move on to phage purification.

Title: Picking a plaque, round 1

Date: September 13, 2021 Redo: No Sample: #4

Purpose: This procedure is to retrieve a phage particle from a plaque and create a liquid sample.

Notes:

- The following materials were collected: agar plates with plaques, microcentrifuge tubes, phage buffer, pipette, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- A small circle by a permanent marker was drawn around the selected plaque and labeled ‘A’.

- The morphology of the plaque was recorded as the largest, clear plaque.

- A microcentrifuge tube was labeled ‘Sample 4:A’ and 100μl of phage buffer was added via micropipette.

- A yellow pipette tip was placed on the pipettor.

- The pipettor was lowered perpendicular to the agar plate of plaques and gently stabbed into the middle of the plaque labeled ‘A’.

- The end of the pipettor tip was placed in the microcentrifuge tube of phage buffer and tapped against the walls of the tube.

- The phage buffer was immediately aspirated and released back into the tube several times to dislodge the phage.

- The phage buffer and phage particle were mixed by vortex.

Results:

No photos of the microcentrifuge tube were taken.

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, round one serial dilution.

Title: Serial Dilutions, round 1

Date: September 13, 2021 Redo: Yes Sample: #4

Purpose: This procedure is to prepare five liquid phage samples of decreasing concentrations.

Notes:

- The following materials were collected: microcentrifuge tube with liquid phage sample, microcentrifuge tubes, phage buffer, pipette, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- Five microcentrifuge tubes were labeled 10⁻¹, 10⁻², 10⁻³, 10⁻⁴, and 10⁻⁵ respectively.

- 90μl of phage buffer was added to each tube via micropipette.

- 10μl of the undiluted liquid phage sample was pipetted via micropipette into the 10⁻¹ labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻¹ labeled microcentrifuge and placed in the 10⁻² labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻² labeled microcentrifuge and placed in the 10⁻³ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻³ labeled microcentrifuge and placed in the 10⁻⁴ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻⁴ labeled microcentrifuge and placed in the 10⁻⁵ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

Results:

No photos of the microcentrifuge tubes were taken.

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, plaque assay round 1.

Title: Plaque Assay, round 1

Date: September 13, 2021 Redo: No Sample: #4

Purpose: This procedure is to confirm the presence of phage particles on bacterial lawns from the diluted liquid phage samples.

Notes:

- The following materials were collected: microcentrifuge tubes with liquid phage samples, host bacteria (250μl), 5ml serological pipette, molten top agar, agar plates, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- 10μl of liquid phage sample 10⁻¹ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻¹ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻² was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻² was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻³ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻³ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻⁴ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻⁴ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻⁵ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻⁵ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into each tube of m. foliorum/diluted liquid phage sample 10⁻¹, m. foliorum/diluted liquid phage sample 10⁻², m. foliorum/diluted liquid phage sample 10⁻³, m. foliorum/diluted liquid phage sample 10⁻⁴, m. foliorum/diluted liquid phage sample 10⁻⁵ respectively.

- Immediately after releasing the top agar into each tube, the top agar and bacterial host/diluted liquid phage sample were aspirated and placed in a petri dish for each m. foliorum/diluted liquid phage sample.

- Each petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once each plate had the mixture solidify, each petri dish was flipped over and placed in the incubator for approximately 1 day.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of each plate, the diluted liquid phage samples of Sample #4:A was moved to the refrigerator.

Results:

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, round two picking a plaque.

Title: Picking a plaque, round 2

Date: September 15, 2021 Redo: No Sample: #4

Purpose: This procedure is to retrieve a phage particle from a plaque and create a liquid sample.

Notes:

- The following materials were collected: agar plates with plaques, microcentrifuge tubes, phage buffer, pipette, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- A small circle by a permanent marker was drawn around the selected plaque and labeled ‘B’.

- The morphology of the plaque was recorded as the largest, clear plaque.

- A microcentrifuge tube was labeled ‘Sample 4:B’ and 100μl of phage buffer was added via micropipette.

- A yellow pipette tip was placed on the pipettor.

- The pipettor was lowered perpendicular to the agar plate of plaques and gently stabbed into the middle of the plaque labeled ‘B’.

- The end of the pipettor tip was placed in the microcentrifuge tube of phage buffer and tapped against the walls of the tube.

- The phage buffer was immediately aspirated and released back into the tube several times to dislodge the phage.

- The phage buffer and phage particle were mixed by vortex.

Results:

No photos of the microcentrifuge tube were taken.

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, round two serial dilutions.

Title: Serial Dilutions, round 2

Date: September 15, 2021 Redo: Yes Sample: #4

Purpose: This procedure is to prepare five liquid phage samples of decreasing concentrations.

Notes:

- The following materials were collected: microcentrifuge tube with liquid phage sample, microcentrifuge tubes, phage buffer, pipette, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- Five microcentrifuge tubes were labeled 10⁻¹, 10⁻², 10⁻³, 10⁻⁴, and 10⁻⁵ respectively.

- 90μl of phage buffer was added to each tube via micropipette.

- 10μl of the undiluted liquid phage sample was pipetted via micropipette into the 10⁻¹ labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻¹ labeled microcentrifuge and placed in the 10⁻² labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻² labeled microcentrifuge and placed in the 10⁻³ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻³ labeled microcentrifuge and placed in the 10⁻⁴ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted liquid phage sample was pipetted via micropipette from the 10⁻⁴ labeled microcentrifuge and placed in the 10⁻⁵ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

Results:

No photos of the microcentrifuge tubes were taken.

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, round 2 plaque assay.

Title: Plaque Assay, round 2

Date: September 15, 2021 Redo: No Sample: #4

Purpose: This procedure is to confirm the presence of phage particles on bacterial lawns from the diluted liquid phage samples.

Notes:

- The following materials were collected: microcentrifuge tubes with liquid phage samples, host bacteria (250μl), 5ml serological pipette, molten top agar, agar plates, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- 10μl of liquid phage sample 10⁻¹ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻¹ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻² was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻² was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻³ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻³ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻⁴ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻⁴ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of liquid phage sample 10⁻⁵ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and liquid phage sample 10⁻⁵ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into each tube of m. foliorum/diluted liquid phage sample 10⁻¹, m. foliorum/diluted liquid phage sample 10⁻², m. foliorum/diluted liquid phage sample 10⁻³, m. foliorum/diluted liquid phage sample 10⁻⁴, m. foliorum/diluted liquid phage sample 10⁻⁵ respectively.

- Immediately after releasing the top agar into each tube, the top agar and bacterial host/diluted liquid phage sample were aspirated and placed in a petri dish for each m. foliorum/diluted liquid phage sample.

- Each petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once each plate had the mixture solidify, each petri dish was flipped over and placed in the incubator for approximately 1 day.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of each plate, the diluted liquid phage samples of Sample #4:B was moved to the refrigerator.

Results:

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, collecting plate lysates.

Title: Purification- Collecting Plate Lysate

Date: September 20, 2021 Redo: No Sample: #4

Purpose: This procedure is to generate a highly concentrated liquid phage sample.

Notes:

- The following materials were collected: a webbed plate, 5ml serological pipette, phage buffer, sterile 5ml syringe, 0.22 μm syringe filter, 15ml conical tube, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- 4ml of phage buffer was added to the webbed plate via serological pipette.

- 4ml of phage buffer was added to the webbed plate via serological pipette a second time.

- The webbed plate was lightly swirled and left undisturbed on the workbench for approximately 8 hours.

- After the incubation time was completed the student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The lid of the flooded plate was removed.

- The plate was tilted by being placed on the edge of the lid to pool the liquids to one side of the plate.

- A 5ml syringe was used to aspirate the lysate.

- A 0.22 μm filter was attached to the 5ml syringe.

- The lysate was filtered into the 15ml conical tube and stored in the fridge at 4 °C.

Results:

No photos of the 15ml conical tube were taken.

Conclusions and Next Steps:

Group members will move on to the next step of the phage purification process, full plate titer.

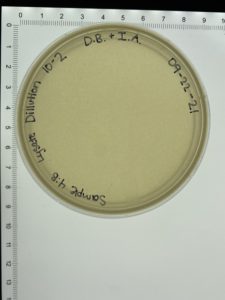

Title: Purification- Full Plate Titer

Date: September 22, 2021 Redo: No Sample: #4

Purpose: This procedure is to determine the concentration of phage particles in a lysate by using a plaque assay.

Notes:

- The following materials were collected: lysate, 5ml serological pipette, phage buffer, agar plates, molten top agar, microcentrifuge tubes, host bacteria (250μl), and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The student’s prepared a series of serial dilutions.

- Six microcentrifuge tubes were labeled 10⁻¹, 10⁻², 10⁻³, 10⁻⁴, 10⁻⁵, and 10⁻⁶ respectively.

- 90μl of phage buffer was added to each tube via micropipette.

- 10μl of the filtered lysate was pipetted via micropipette into the 10⁻¹ labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of diluted filtered lysate sample was pipetted via micropipette from the 10⁻¹ labeled microcentrifuge and placed in the 10⁻² labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted filtered lysate sample was pipetted via micropipette from the 10⁻² labeled microcentrifuge and placed in the 10⁻³ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted filtered lysate sample was pipetted via micropipette from the 10⁻³ labeled microcentrifuge and placed in the 10⁻⁴ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted filtered lysate sample was pipetted via micropipette from the 10⁻⁴ labeled microcentrifuge and placed in the 10⁻⁵ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of diluted filtered lysate sample was pipetted via micropipette from the 10⁻⁵ labeled microcentrifuge and placed in the 10⁻⁶ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the diluted filtered lysate sample 10⁻¹ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted filtered lysate sample 10⁻¹ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted filtered lysate sample 10⁻² was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted filtered lysate sample 10⁻² was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted filtered lysate sample 10⁻³ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted filtered lysate sample 10⁻³ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted filtered lysate sample 10⁻⁴ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted filtered lysate sample 10⁻⁴ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted filtered lysate sample 10⁻⁵ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted filtered lysate sample 10⁻⁵ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted filtered lysate sample 10⁻⁶ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted filtered lysate sample 10⁻⁶ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into each tube of m. foliorum/diluted filtered lysate sample 10⁻¹, m. foliorum/diluted filtered lysate sample 10⁻², m. foliorum/diluted filtered lysate sample 10⁻³, m. foliorum/diluted filtered lysate sample 10⁻⁴, m. foliorum/diluted filtered lysate sample 10⁻⁵, and m. foliorum/diluted filtered lysate sample 10⁻⁶ respectively.

- Immediately after releasing the top agar into each tube, the top agar and bacterial host/diluted liquid phage sample were aspirated and placed in a petri dish for each m. foliorum/diluted filtered lysate sample.

- Each petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once each plate had the mixture solidify, each petri dish was flipped over and placed in the incubator for approximately 1 day.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of each plate, the diluted filtered lysate sample of Sample #4:B: Lysate was wrapped and placed in the fridge.

- On September 27, 2021, the students recorded the number of plaques on the 10⁻⁶ plate as 126 plaques.

- The titer was then calculated: Titer (pfu/ml) = (126 pfu/10 μl) x (10₃ μl/ ml) x (10₆) = (12.6 x 10₃ x 10₆) pfu/ml = 12.6 x 10₉ pfu/ml

Results:

Conclusions and Next Steps:

Group members will move on to the next step, phage amplification.

Amplification

Title: Making Webbed Plates From a Lysate of Known Titer

Date: September 27, 2021 Redo: No Sample: #4B

Purpose: This procedure is to create a plate with a very high density of plaques from a lysate of a known titer.

Notes:

- The following materials were collected: lysate, 5ml serological pipette, phage buffer, agar plates, molten top agar, microcentrifuge tube, host bacteria (250μl), and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The volume of lysate needed for the webbed plates was calculated as follows: Volume needed (ml)lysate = (1.26×10⁵ pfu) / (1.26×10¹⁰ pfu/ml) = 1×10⁻⁵ ml lysate = (1×10⁻⁵ ml) x (1000 μl/ml) = 1×10⁻² μl

- One microcentrifuge tube was labeled “Webbed Lysate”.

- 99μl of phage buffer was added to the tube via micropipette.

- 1μl of the lysate was pipetted via micropipette into the “Webbed Lysate” labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of the diluted lysate sample was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted lysate sample were gently flicked with a finger and left to sit undisturbed for 10 minutes.

- Steps 11 and 12 were done six times in total.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into each of the six tubes of m. foliorum/diluted lysate sample.

- Immediately after releasing the top agar into each tube, the top agar and bacterial host/diluted lysate were aspirated and placed in a petri dish for each m. foliorum/diluted lysate sample.

- Each petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once each plate had the mixture solidify, each petri dish was flipped over and placed in the incubator for approximately one day.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of each plate, the plates of the diluted lysate sample of Sample #4:B: Lysate was wrapped and placed in the fridge.

Results:

Conclusions and Next Steps:

Group members are unclear if the webbed plate protocol was performed correctly due to no plaques being formed. Members are confirming with the professor. Confirmation with the professor determined that a second webbed plate dilution was to be performed.

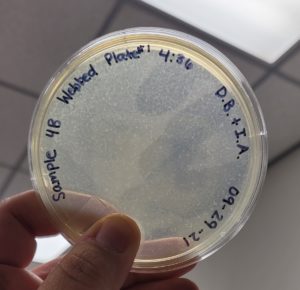

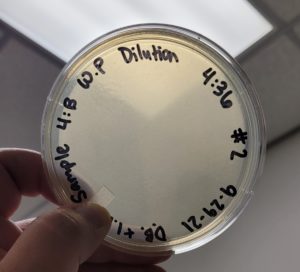

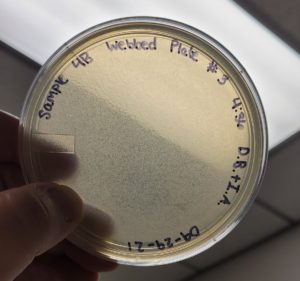

Title: Making Webbed Plates From a Lysate of Known Titer

Date: September 29, 2021 Redo: Yes Sample: #4B

Purpose: This procedure is to create a plate with a very high density of plaques from a lysate of known titer.

Notes:

- The following materials were collected: lysate, 5ml serological pipette, phage buffer, agar plates, molten top agar, microcentrifuge tube, host bacteria (250μl), and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The volume of lysate needed for the webbed plates was calculated as follows: Volume needed (ml)lysate = (1.26×10⁵ pfu) / (1.26×10¹⁰ pfu/ml) = 1×10⁻⁵ ml lysate = (1×10⁻⁵ ml) x (1000 μl/ml) = 1×10⁻² μl

- One microcentrifuge tube was labeled “2:18”.

- 18μl of phage buffer was added to the tube via micropipette.

- 2μl of the lysate was pipetted via micropipette into the “2:18” labeled microcentrifuge and then flicked with a finger and inverted.

- One microcentrifuge tube was labeled “4:36”.

- 36μl of phage buffer was added to the tube via micropipette.

- 4μl of the diluted lysate was pipetted via micropipette from the tube labeled “2:18” into the “4:36” labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of the diluted lysate sample was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted lysate sample were gently flicked with a finger and left to sit undisturbed for 10 minutes.

- Steps 14 and 15 were done four times in total.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into each of the four tubes of m. foliorum/diluted lysate sample.

- Immediately after releasing the top agar into each tube, the top agar and bacterial host/diluted lysate were aspirated and placed in a petri dish for each m. foliorum/diluted lysate sample.

- Each petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once each plate had the mixture solidify, each petri dish was flipped over and placed in the incubator for approximately one day.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of each plate, we began our next step, flooding the plates of the diluted lysate sample of Sample #4:B.

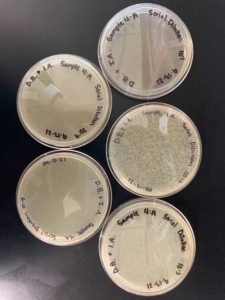

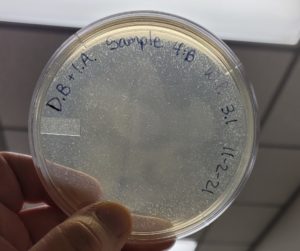

Results:

Conclusions and Next Steps:

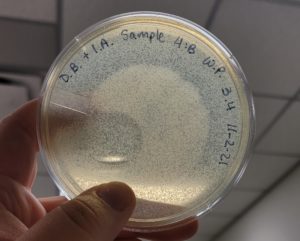

The second round of making webbed plates with Sample #4:B produced a high titer webbed plate required to proceed to our next step of flooding the plates and retrieve a high titer lysate.

Title: Collecting a Plate Lysate

Date: September 30, 2021 Redo: No Sample: #4:B

Purpose: This procedure is to generate a highly concentrated liquid phage sample.

Notes:

- The following materials were collected: webbed plates, 5ml serological pipette, phage buffer, sterile 5ml syringe, 0.22 μm syringe filter, 50ml conical tube, and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- 8ml of phage buffer was added to each of the 4 webbed plates via a serological pipette.

- The webbed plates were lightly swirled and left undisturbed on the workbench for approximately 5 hours.

- After the incubation time was completed the student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The lid of the flooded plates was removed.

- The plates were tilted by being placed on the edge of the lid to pool the liquids to one side of the plate.

- A 5ml syringe was used to aspirate the lysate from each plate.

- A 0.22 μm filter was attached to the 5ml syringe.

- Approximately 27ml of lysate was filtered into the 50ml conical tube and stored in the fridge at 4 °C.

- The workbench was cleaned and disinfected as described in Steps #2-4.

Results:

No photos of the 50ml conical tube were taken.

Conclusions and Next Steps:

Collecting plate lysate was successful and welded approximately 27 mL of the high titer lysate. Group members will move on to the next step of amplification, a second full plate titer.

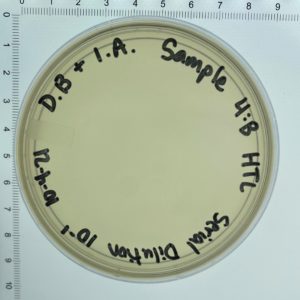

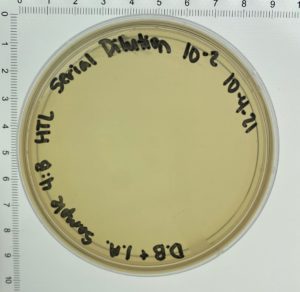

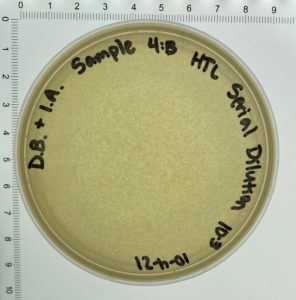

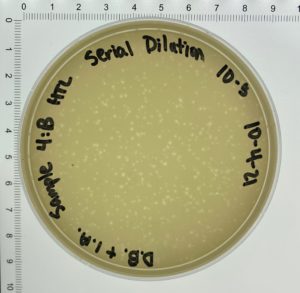

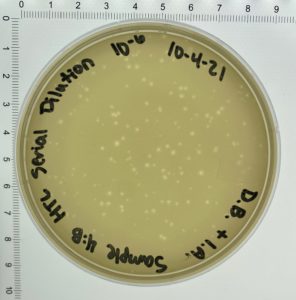

Title: Full Plate Titer

Date: October 4, 2021 Redo: No Sample: #4

Purpose: This procedure is to determine the concentration of phage particles in a lysate by using a plaque assay.

Notes:

- The following materials were collected: lysate, 5ml serological pipette, phage buffer, agar plates, molten top agar, microcentrifuge tubes, host bacteria (250μl), and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The student’s prepared a series of serial dilutions.

- Six microcentrifuge tubes were labeled 10⁻¹, 10⁻², 10⁻³, 10⁻⁴, 10⁻⁵, and 10⁻⁶ respectively.

- 90μl of phage buffer was added to each tube via micropipette.

- 10μl of the high volume lysate was pipetted via micropipette into the 10⁻¹ labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of the diluted high volume lysate sample was pipetted via micropipette from the 10⁻¹ labeled microcentrifuge and placed in the 10⁻² labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the diluted high volume lysate sample was pipetted via micropipette from the 10⁻² labeled microcentrifuge and placed in the 10⁻³ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the diluted high volume lysate sample was pipetted via micropipette from the 10⁻³ labeled microcentrifuge and placed in the 10⁻⁴ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the diluted high volume lysate sample was pipetted via micropipette from the 10⁻⁴ labeled microcentrifuge and placed in the 10⁻⁵ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the diluted high volume lysate sample was pipetted via micropipette from the 10⁻⁵ labeled microcentrifuge and placed in the 10⁻⁶ labeled microcentrifuge and then flicked with a finger and inverted. (a new pipette tip was used for this step)

- 10μl of the the diluted high volume lysate sample 10⁻¹ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the the diluted high volume lysate sample 10⁻¹ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted high volume lysate sample 10⁻² was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted high volume lysate sample 10⁻² was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted high volume lysate sample 10⁻³ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted high volume lysate sample 10⁻³ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted high volume lysate sample 10⁻⁴ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted high volume lysate sample 10⁻⁴ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted high volume lysate sample 10⁻⁵ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted high volume lysate sample 10⁻⁵ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- 10μl of the diluted high volume lysate sample 10⁻⁶ was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted high volume lysate sample 10⁻⁶ was gently flicked with a finger and left to sit undisturbed for 10 minutes.

- At 10 minutes, 3ml of molten top agar was pipetted via a serological pipette into each tube of m. foliorum/diluted high volume lysate sample 10⁻¹, m. foliorum/diluted high volume lysate sample 10⁻², m. foliorum/diluted high volume lysate sample 10⁻³, m. foliorum/diluted high volume lysate sample 10⁻⁴, m. foliorum/diluted high volume lysate sample 10⁻⁵, and m. foliorum/diluted high volume lysate sample 10⁻⁶ respectively.

- Immediately after releasing the top agar into each tube, the top agar and bacterial host/diluted high volume lysate sample were aspirated and placed in a petri dish for each m. foliorum/diluted high volume lysate sample.

- Each petri dish was slightly swirled to ensure the mixture covered the entire plate and was left to sit undisturbed for 20 minutes.

- Once each plate had the mixture solidify, each petri dish was flipped over and placed in the incubator for approximately 1 day.

- The workbench was cleaned and disinfected as described in Steps #2-4.

- After a photo and observations of each plate, diluted high volume lysate sample of Sample #4:B: Lysate was wrapped and placed in the fridge.

- On October 6, 2021, the students recorded the number of plaques on the 10⁻⁶ plate as 204 plaques.

- The titer was then calculated: Titer (pfu/ml) = (204 pfu/10 μl) x (10³ μl/ ml) x (10⁶) = (20.4 x 10³ x 10⁶) pfu/ml = 20.4 x 10⁹ pfu/ml

Results:

Conclusions and Next Steps:

Group members will move on to the next step, archiving your phage sample.

Title: Archiving Your Phage Sample

Date: October 7, 2021 Redo: No Sample: #4

Purpose: This procedure is to prepare a high-titer lysate for long-term storage.

Notes:

- The following materials were collected: high volume lysate, DMSO mixture, 5ml serological pipette, micropipette, sterile beads, and barcoded tubes.

- The student’s hands were washed and gloved.

- All materials used were placed in the biosafety hood for use.

- The phage sample was entered into the Actinobacteriophage database.

- Three barcoded tubes were each filled with sterile beads approximately 1.5cm from the top of the tube.

- 200μl of DMSO was pipetted into the 15ml conical tube via micropipette.

- The original bottle of DMSO was immediately stored away.

- 2.8ml of the high volume lysate was added to the 15ml conical tube containing DMSO via a serological pipette.

- The mixture in the 15ml conical tube was lightly vortexed.

- Approximately 3ml of the lysate/DMSO mixture was aspirated in a serological pipette.

- Each of the barcoded tubes containing sterile beads were filled with the lysate/DMSO mixture from the serological pipette (add enough mixture to just cover the beads).

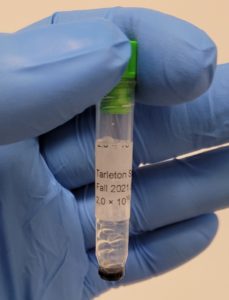

- One tube was photographed for record and all the tubes were placed in the freezer.

Results:

Conclusions and Next Steps:

It was discovered that DMF was used instead of DMSO. The students will redo the archiving protocol.

Title: Archiving Your Phage Sample

Date: October 11, 2021 Redo: Yes Sample: #4

Purpose: This procedure is to prepare a high-titer lysate for long-term storage.

Notes:

- The following materials were collected: high volume lysate, DMSO mixture, 5ml serological pipette, micropipette, sterile beads, and barcoded tubes.

- The student’s hands were washed and gloved.

- All materials used were placed in the biosafety hood for use.

- Three barcoded tubes were each filled with sterile beads approximately 1.5cm from the top of the tube.

- 200μl of DMSO was pipetted into the 15ml conical tube via micropipette.

- 2.8ml of the high volume lysate was added to the 15ml conical tube containing DMSO via a serological pipette.

- The mixture in the 15ml conical tube was lightly vortexed.

- Approximately 3ml of the lysate/DMSO mixture was aspirated in a serological pipette.

- Each of the barcoded tubes containing sterile beads were filled with the lysate/DMSO mixture from the serological pipette (add enough mixture to just cover the beads).

- One tube was photographed for record and all the tubes were placed in the freezer.

Results:

Conclusions and Next Steps:

Group members will now move on to the next step, DNA extraction.

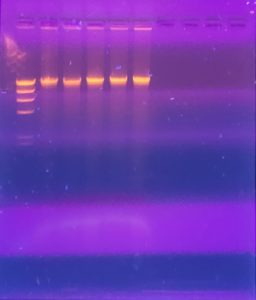

DNA Extraction

Title: Phage DNA Extraction #1

Date: 10/11/2021 Redo: No Sample: #4

Purpose: This procedure is to isolate genomic DNA from phage.

Notes:

- The following materials were collected: high volume lysate, nuclease mix 0.5M EDTA, 2M ZnCl₂, TES buffer, 10mg/mL Proteinase K, 3M potassium acetate, pH 5.2, Isopropanol, 70% ethanol, Nuclease-free water, heat block, ice, 5ml serological pipettes, and micropipettes.

- The student’s hands were washed and gloved.

- The high volume lysate was gently mixed.

- 5mL of the lysate was pipette into a 15 mL conical tube via serological pipette.

- The tube was then given to the TA, Marlee Goppert, who added 20μl of nuclease to the tube.

- The tube was gently inverted and incubated at 37°C for 10 minutes.

- 1ml of the lysate/nuclease mixture was pipetted into 5 microcentrifuge tubes each.

- 20μl of ZnCl₂ was added to each tube via micropipette after incubation was complete.

- The tube was gently inverted and incubated at 37°C for 5 minutes.

- The tube was then placed in the centrifuge at 4°C at 10,000rpm for 1 minute.

- Supernatants (liquid) was then removed via serological pipette.

- The liquid supernatants were stored in a 15ml conical tube in the refrigerator.

- 500μl of TES buffer was added to each tube of pellets and incubated at 60°C for 15 minutes.

- 1μl of Proteinase K was added to each tube via micropipette and mixed gently.

- Each tube incubated at 37°C for 10 minutes.

- 60μl of potassium acetate was added to each tube via micropipette.

- Each tube was mixed well and left on ice for 15 minutes.

- Each tube was placed in the centrifuge at 4°C at 12,000rpm for 1 minute.

- The supernatants were pipetted via serological pipette into 5 new microcentrifuge tubes.

- The old microcentrifuge tubes containing the pellets were autoclaved.

- 500μl of isopropanol was added to each of the tubes with the supernatant via micropipette.

- The tubes were gently mixed, left on ice, and placed in the refrigerator for overnight storage.

- The next afternoon, the tubes were centrifuged at 12,000rpm for 10 minutes.

- After the centrifuge was complete, the supernatant was collected by slightly tilting each tube in the direction of the pellet and pipetting the supernatant out.

- The supernatant from each tube was released into a 15ml conical tube.

- The 15ml conical tube was dumped down the sink drain and autoclaved.

- 250μl of 70% ethanol was added to each tube via micropipette.

- Each tube was centrifuged for 1 minute at 12,000rpm.

- Each tube was gently dumped out onto a folded kim-wipe and placed under the biosafety hood to dry.

- 50μl of nuclease-free water was added via micropipette to tube 1.

- The same 50μl of nuclease-free water was added via micropipette to tube 2 leaving tube 1 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 3 leaving tube 2 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 4 leaving tube 3 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 5 leaving tube 4 empty.

- Tube 5 was the final tube containing the phage DNA sample.

- 1μl of nuclease-free water was released on the Nanodrop pedestal to calibrate the Nanodrop.

- The pedestal was then wiped with a kim-wipe.

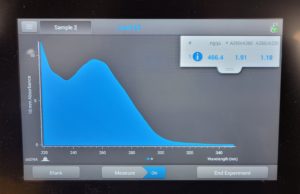

- 1μl of the DNA sample was released on the Nanodrop pedestal.

- The DNA concentration was recorded as 116.6ng/μl, A260/280 = 2.01, and A260/230 = 1.06.

Results:

Conclusions and Next Steps:

Group members will now complete the DNA extraction protocol to retrieve a higher volume of DNA.

Title: Phage DNA Extraction #2

Date: 10/13/2021 Redo: Yes Sample: #4B 1.2 Group Members: Dasire Brawley, Ivy Adame

Purpose: This procedure is to isolate genomic DNA from phage.

Notes:

- The following materials were collected: high volume lysate, nuclease mix 0.5M EDTA, 2M ZnCl₂, TES buffer, 10mg/mL Proteinase K, 3M potassium acetate, pH 5.2, Isopropanol, 70% ethanol, Nuclease-free water, heat block, ice, 5ml serological pipettes, and micropipettes.

- The student’s hands were washed and gloved.

- The high volume lysate was gently mixed.

- 5mL of the lysate was pipette into a 15 mL conical tube via serological pipette.

- The tube was then given to the TA, Marlee Goppert, who added 20μl of nuclease to the tube.

- The tube was gently inverted and incubated at 37°C for 10 minutes.

- 1ml of the lysate/nuclease mixture was pipetted into 5 microcentrifuge tubes each.

- 20μl of ZnCl₂ was added to each tube via micropipette after incubation was complete.

- The tube was gently inverted and incubated at 37°C for 5 minutes.

- The tube was then placed in the centrifuge at 4°C at 14,000rpm for 1 minute.

- Supernatants (liquid) was then removed via serological pipette.

- The liquid supernatants were stored in a 15ml conical tube in the refrigerator.

- 500μl of TES buffer was added to each tube of pellets and incubated at 60°C for 15 minutes.

- 1μl of Proteinase K was added to each tube via micropipette and mixed gently.

- Each tube incubated at 37°C for 10 minutes.

- 60μl of potassium acetate was added to each tube via micropipette.

- Each tube was mixed well and left on ice for 15 minutes.

- Each tube was placed in the centrifuge at 4°C at 14,000rpm for 1 minute.

- The supernatants were pipetted via serological pipette into 5 new microcentrifuge tubes.

- The old microcentrifuge tubes containing the pellets were autoclaved.

- 500μl of isopropanol was added to each of the tubes with the supernatant via micropipette.

- The tubes were gently mixed, left on ice, and placed in the refrigerator for overnight storage.

- The next morning, the tubes were centrifuged at 14,000rpm for 10 minutes.

- After the centrifuge was complete, the supernatant was collected by slightly tilting each tube in the direction of the pellet and pipetting the supernatant out.

- The supernatant from each tube was released into a 15ml conical tube.

- The 15ml conical tube was dumped down the sink drain and autoclaved.

- 250μl of 70% ethanol was added to each tube via micropipette.

- Each tube was centrifuged for 1 minute at 14,000rpm.

- Each tube was gently turned upside down onto a folded kim-wipe and placed under the biosafety hood to dry.

- 50μl of nuclease-free water was added via micropipette to tube 1.

- Then from tube 1, 50μl of nuclease-free water was aspirated and added via micropipette to tube 2 leaving tube 1 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 3 leaving tube 2 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 4 leaving tube 3 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 5 leaving tube 4 empty.

- Tube 5 was the final tube containing the phage DNA sample.

- 1μl of nuclease-free water was released on the Nanodrop pedestal to calibrate the Nanodrop.

- The pedestal was then wiped with a kim-wipe.

- 1μl of the DNA sample was released on the Nanodrop pedestal.

- The DNA concentration was recorded as 36.3ng/μl, A260/280 = 1.92, and A260/230 = 0.92.

Results:

Conclusions and Next Steps:

Group members will now complete the DNA extraction protocol to retrieve a higher volume of DNA and DNA purity.

Title: Phage DNA Extraction #3

Date: 10/18/2021 Redo: Yes Sample: #4B

Purpose: This procedure is to isolate genomic DNA from phage.

Notes:

- The following materials were collected: high volume lysate, nuclease mix 0.5M EDTA, 2M ZnCl₂, TES buffer, 10mg/mL Proteinase K, 3M potassium acetate, pH 5.2, Isopropanol, 70% ethanol, Nuclease-free water, heat block, ice, 5ml serological pipettes, and micropipettes.

- The student’s hands were washed and gloved.

- The high volume lysate was gently mixed.

- 5mL of the lysate was pipette into a 15 mL conical tube via serological pipette.

- The tube was then given to the TA, Marlee Goppert, who added 20μl of nuclease to the tube.

- The tube was gently inverted and incubated at 37°C for 10 minutes.

- 1ml of the lysate/nuclease mixture was pipetted into 5 microcentrifuge tubes each.

- 20μl of ZnCl₂ was added to each tube via micropipette after incubation was complete.

- The tube was gently inverted and incubated at 37°C for 5 minutes.

- The tube was then placed in the centrifuge at 4°C at 14,000rpm for 1 minute.

- Supernatants (liquid) was then removed via serological pipette.

- The liquid supernatants were stored in a 15ml conical tube in the refrigerator.

- 500μl of TES buffer was added to each tube of pellets and incubated at 60°C for 15 minutes.

- 1μl of Proteinase K was added to each tube via micropipette and mixed gently.

- Each tube incubated at 37°C for 10 minutes.

- 60μl of potassium acetate was added to each tube via micropipette.

- Each tube was mixed well and left on ice for 15 minutes.

- Each tube was placed in the centrifuge at 4°C at 14,000rpm for 1 minute.

- The supernatants were pipetted via serological pipette into 5 new microcentrifuge tubes.

- The old microcentrifuge tubes containing the pellets were autoclaved.

- 500μl of isopropanol was added to each of the tubes with the supernatant via micropipette.

- The tubes were gently mixed, left on ice, and placed in the refrigerator for overnight storage.

- Two mornings later (during the next class day), the tubes were centrifuged at 14,000rpm for 10 minutes.

- After the centrifuge was complete, the supernatant was collected by slightly tilting each tube in the direction of the pellet and pipetting the supernatant out.

- The supernatant from each tube was saved in the serological pipette and discarded in the autoclave.

- 250μl of 70% ethanol was added to each tube via micropipette.

- Each tube was centrifuged for 1 minute at 14,000rpm.

- Each tube had the supernatant pipetted out via micropipette and then discarded in the red bucket on the lab bench.

- All 5 microcentrifuge tubes were placed in a heat block at 60°C with their lids open and the heat block lid closed for 10 minutes to dry the tubes.

- 50μl of nuclease-free water was added via micropipette to tube 1.

- Then from tube 1, 50μl of nuclease-free water was aspirated and added via micropipette to tube 2 leaving tube 1 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 3 leaving tube 2 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 4 leaving tube 3 empty.

- Then the same 50μl of nuclease-free water was added via micropipette to tube 5 leaving tube 4 empty.

- Tube 5 was the final tube containing the phage DNA sample.

- 1μl of nuclease-free water was released on the Nanodrop pedestal to calibrate the Nanodrop.

- The pedestal was then wiped with a kim-wipe.

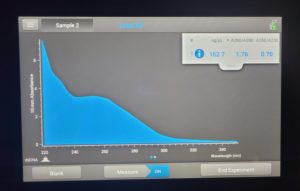

- 1μl of the DNA sample was released on the Nanodrop pedestal.

- The DNA concentration was recorded as 162.7ng/μl, A260/280 = 1.76, and A260/230 = 0.70.

Results:

Conclusions and Next Steps:

Group members will now purify the three samples of DNA to yield a higher concentration and lower pollutants.

Title: DNA Precipitation #1

Date: 10/27/2021 Redo: No Sample: #4B

Purpose: This procedure is to purify the extracted DNA from a phage.

Notes:

- The following materials were collected: 3M Sodium Acetate, ice-cold 100% Ethanol, extracted DNA from phage samples, micropipettes, microcentrifuge tube.

- The student’s hands were washed and gloved.

- The three microcentrifuge tubes containing the extracted DNA were collected.

- All three tubes had the DNA samples extracted via micropipette, the volume recorded and aspirated into one final microcentrifuge tube.

- The final volume of the extracted DNA was 116μl.

- 11.6μl of Sodium acetate was added to the tube of DNA and was calculated by dividing the final DNA volume by 10.

- 348μl of 100% Ethanol was added to the tube of DNA/Sodium acetate and was calculated by multiplying the final DNA volume by 3.

- The tube was vortexed lightly (on 5) and given to the TA, Marlee, to be stored in Dr. Edwards’ -80°C freezer overnight for 5 days.

- After 5 days, the tube was placed in the centrifuge at 14,000rpm at 4°C for 30 minutes.

- After 30 minutes, the supernatant was removed via pipette and the pellet was left in the tube.

- 0.5ml of ice-cold 75% Ethanol was added to the tube with the pellet and placed in the centrifuge at 14,000rpm at 4°C for 10 minutes.

- After 10 minutes, the supernatant was removed via pipette and the pellet was left in the tube.

- 0.5ml of ice-cold 75% Ethanol was added to the tube for a second time with the pellet and placed in the centrifuge at 14,000rpm at 4°C for 10 minutes.

- After 10 minutes, the supernatant was removed via pipette and the pellet was left in the tube.

- The tube was placed in the centrifuge on the lab bench for 1 minute at top speed.

- The tube was placed in a heat block at 37°C for 10 minutes to dry.

- After the pellet was dried, 50μl of nuclease-free water was added to the tube via pipette.

- The tube was gently flicked with a finger 4 times.

- 1μl of nuclease-free water was released on the Nanodrop pedestal to calibrate the Nanodrop.

- The pedestal was then wiped with a kim-wipe.

- 1μl of the precipitated DNA sample was released on the Nanodrop pedestal.

- The DNA concentration was recorded as 49.6ng/μl, A260/280 = 1.82, and A260/230 = 1.35.

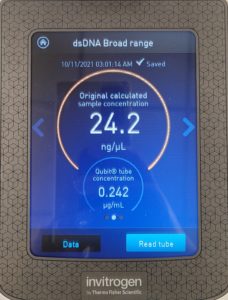

- The DNA was tested in the Qubit 3:

- Three microcentrifuge tubes were retrieved from the bag next to the Qubit.

- One 1.5 microcentrifuge tube was collected.

- 796μl of broad range Qubit buffer was added to the 1.5 microcentrifuge tube via micropipette.

- 4μl of broad range reagent dye was added to the tube of buffer via micropipette.

- The tube was lightly vortexed.

- The three small tubes were labeled “1, 2, and D” respectively.

- 190μl of the buffer/dye solution was added to each tube labeled “1” and “2” via micropipette.

- 198μl of the buffer/dye solution was added to the tube labeled “D” via micropipette.

- 10μl of standard 1 was added to the tube labeled “1” via micropipette.

- 10μl of standard 2 was added to the tube labeled “2” via micropipette.

- 2μl of the DNA to be tested was added to the tube labeled “D” via micropipette.

- All three tubes were vortexed lightly and left to sit undisturbed for 2 minutes.

- The Qubit was plugged in.

- Double stranded DNA was selected.

- Broad range was selected.

- The button “read standards” was selected.

- Tube 1 was placed into the slot and the “read standard” button was selected.

- Tube 1 was removed.

- Tube 2 was placed into the slot and the “read standard” button was selected.

- Tube 2 was removed.

- Tube D was placed into the slot and the “read sample” button was selected.

- A photo of the results was taken and tube D was removed.

- All four tubes were then autoclaved.

Results:

Conclusions and Next Steps:

Group members will make more high titer lysate and perform the DNA extraction protocol again.

Title: Making Webbed Plates From a Lysate of Known Titer

Date: 11/1/2021 Redo: Yes Sample: #4B

Purpose: This procedure is to create a plate with a very high density of plaques from a lysate of a known titer.

Notes:

- The following materials were collected: lysate, 10ml serological pipette, phage buffer, agar plates, molten top agar, microcentrifuge tube, host bacteria (250μl), and a bunsen burner.

- The student’s hands were washed and gloved prior to disinfecting the workstation.

- CiDecon was spread with Kim-Wipes to disinfect the workstation.

- 70% Ethanol alcohol was sprayed on the workstation and wiped after with Kim-Wipes to speed drying.

- Gloves were removed after disinfecting to prevent burns on the next step.

- A bunsen burner station was set up to prevent contamination.

- The volume of lysate needed for the webbed plates was calculated as follows: Volume needed (ml)lysate = (1.26×10⁵ pfu) / (1.26×10¹⁰ pfu/ml) = 1×10⁻⁵ ml lysate = (1×10⁻⁵ ml) x (1000 μl/ml) = 1×10⁻² μl

- One microcentrifuge tube was labeled “2:18”

- 18μl of phage buffer was added to the tube via micropipette

- 2μl of the lysate was pipetted via micropipette into the “2:18” labeled microcentrifuge and then flicked with a finger and inverted

- One microcentrifuge tube was labeled “4:36”.

- 36μl of phage buffer was added to the tube via micropipette.

- 4μl of the diluted lysate was pipetted via micropipette from the tube labeled “2:18” into the “4:36” labeled microcentrifuge and then flicked with a finger and inverted.

- 10μl of the diluted lysate sample was pipetted via micropipette into a tube containing 250μl of our bacterial host microbacterium foliorum.

- The tube of m. foliorum and the diluted lysate sample were gently flicked with a finger and left to sit undisturbed for 10 minutes.

- Steps 14 and 15 were done four times in total.